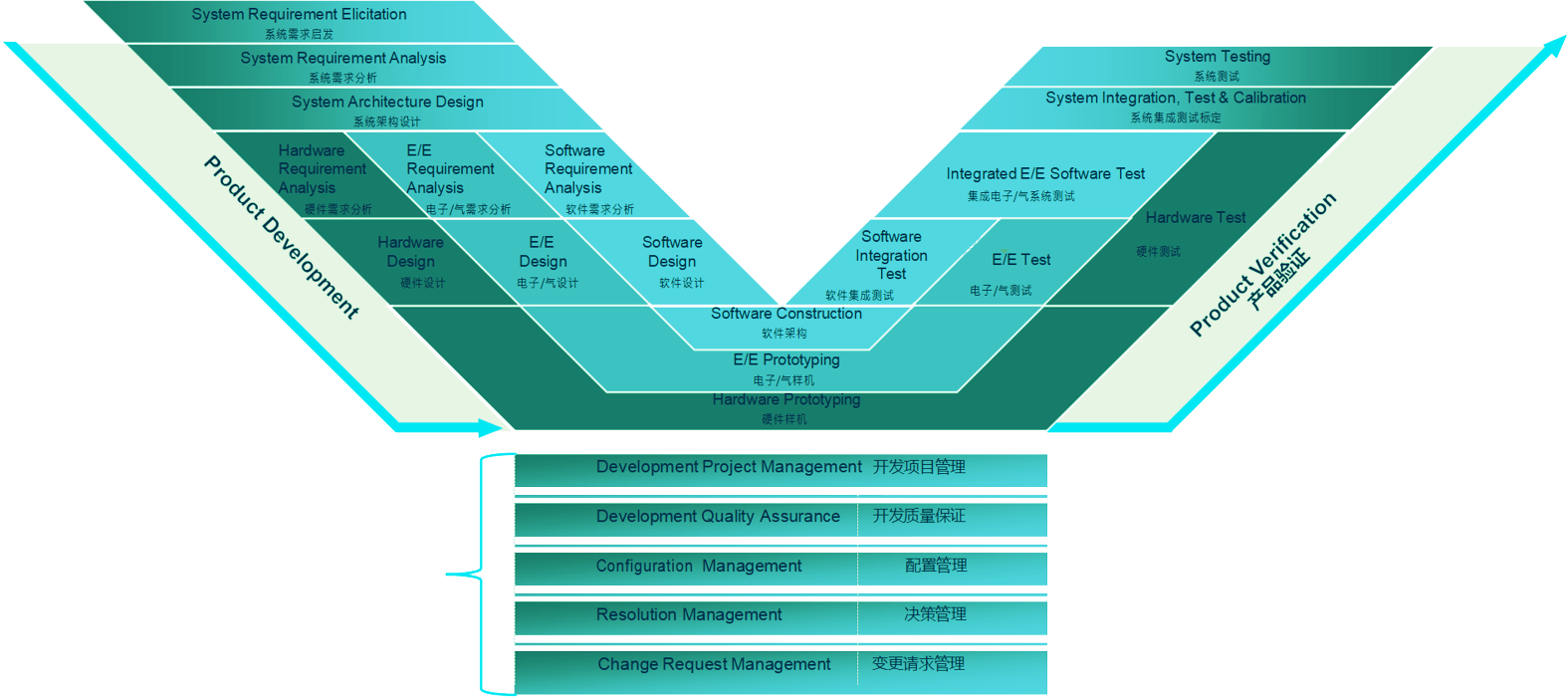

Development process

Development steps

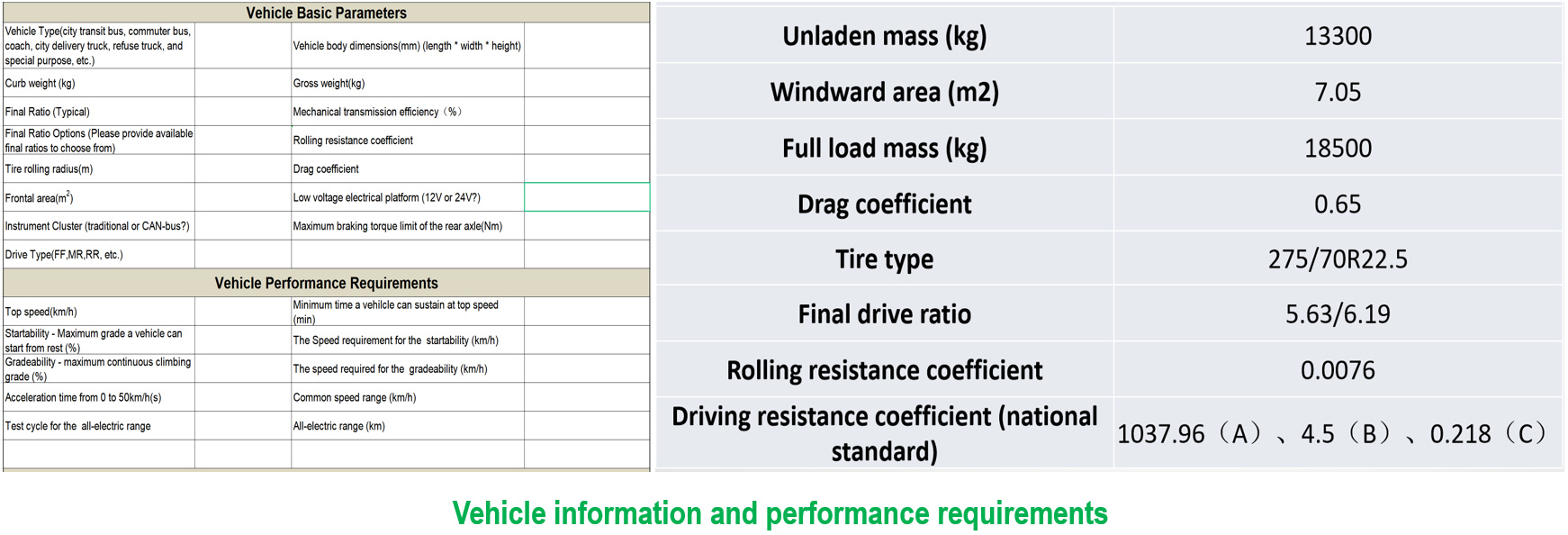

Collection of vehicle operation environment information, road condition information, operation information and basic vehicle status information.

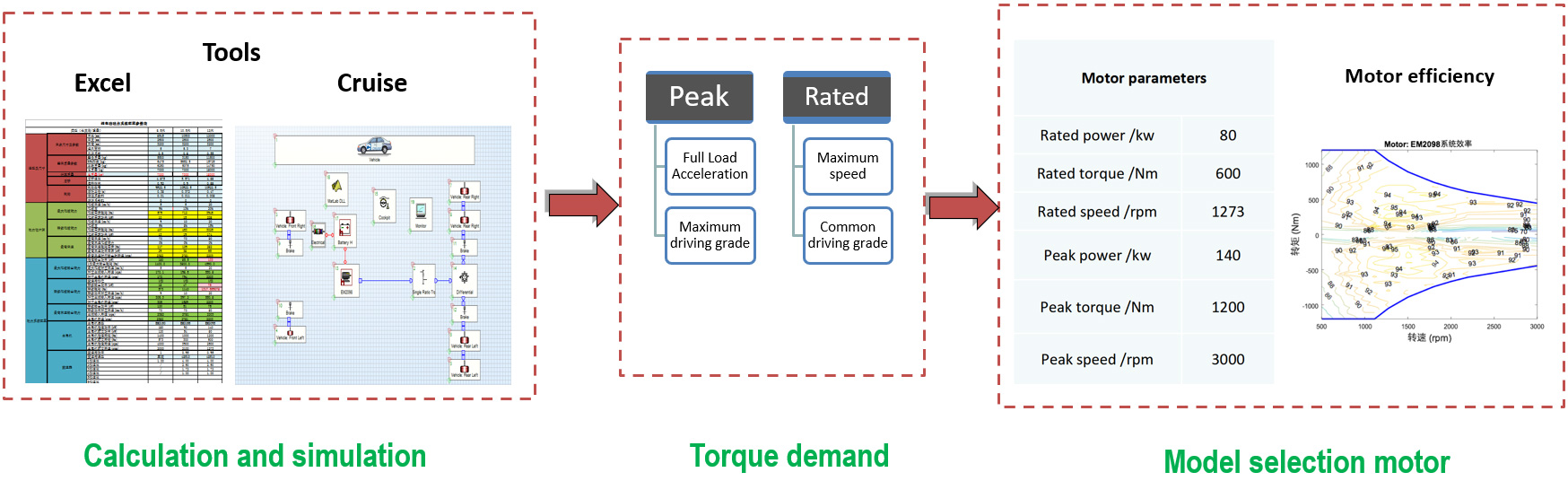

According to the vehicle parameters and power demand information, firstly calculate the torque interval of the motor demand, select the appropriate power motor according to the torque status, and finally finalize the design according to the project status.

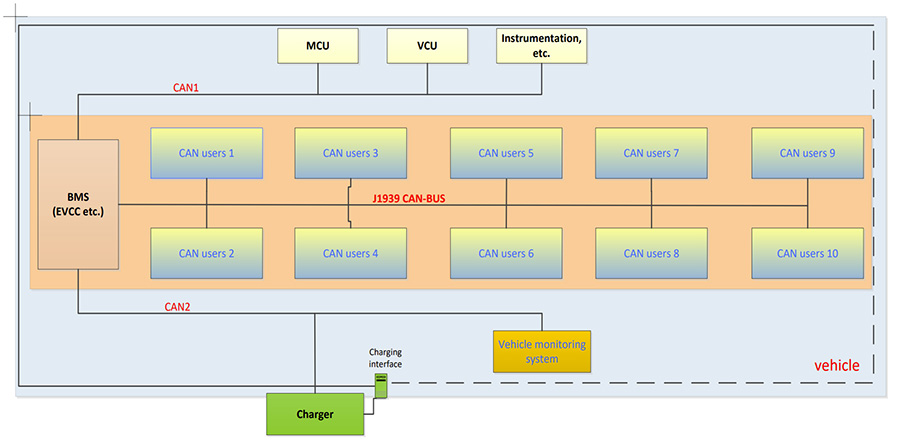

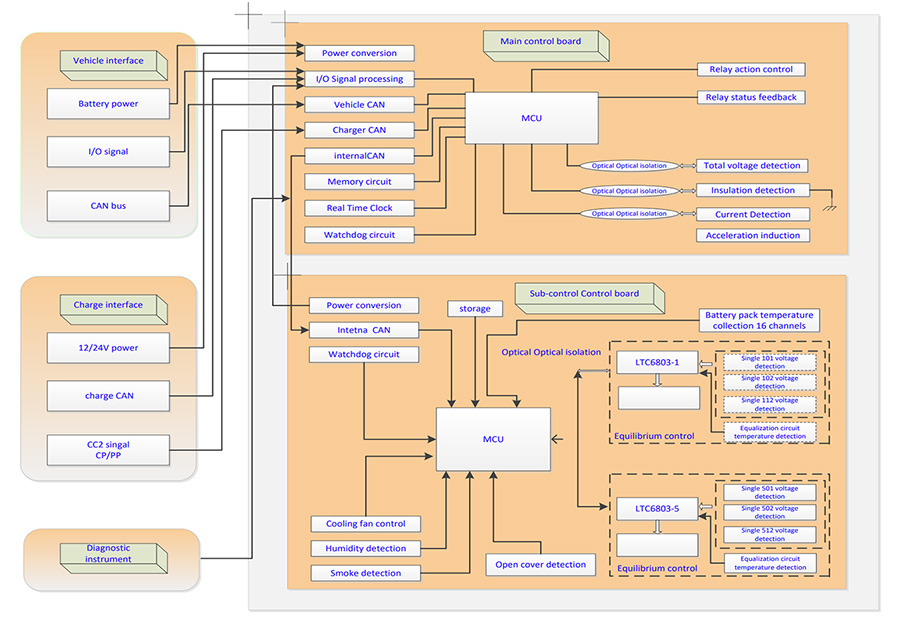

According to the motor parameter information and vehicle status information, select the MCU, select the high-voltage accessories, clarify the principle of the high-voltage and low-voltage system of the vehicle, and determine the components of the BMS and PDU high-voltage system according to the battery information to ensure that the system has no redundant design and works reliably.

According to the matched power system and vehicle electrical structure status, first define the CAN communication network architecture to ensure that vehicle communication is not redundant, safe and reliable.

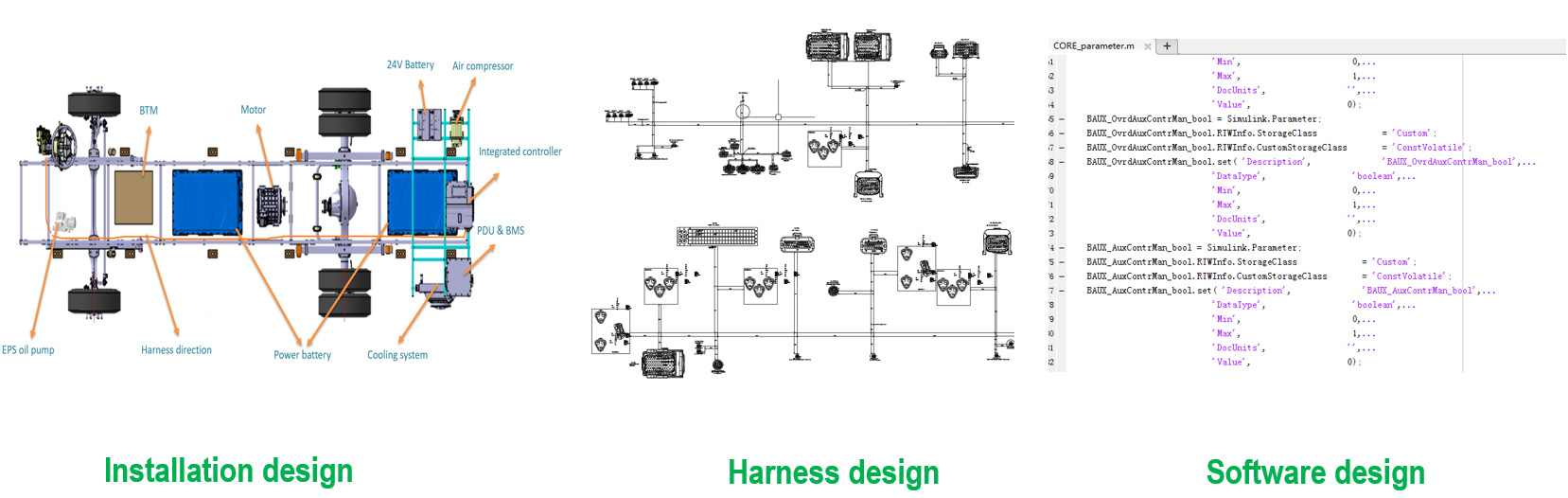

Finally, according to the planning, carry out parts layout design, high and low voltage electrical schematic design, high and low voltage harness design, software compilation, simulation test and parts installation design.

Testing

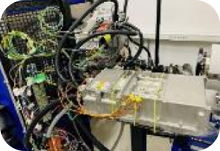

Build Release Test“EOL-Type”Test

Control Object Test “F1 Test”

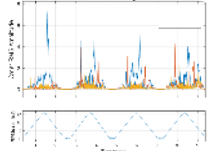

Efficiency & DragTorque Test

Contact Pattern Test

NVH (VibrationFocus) Test

...

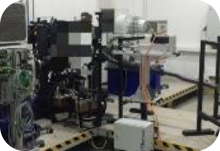

PowertrainDurability Test

System Durability Test

High Speed Test

Sub system Test

Heat CycleTest

...

Applicable vehicles